Key questions:

- What are your key quality objectives and how will the system support them?

- Does the system comply with industry standards and regulations?

- How will it integrate with your current processes and technology?

- What level of customization and scalability do you require?

- How will you assess the system’s effectiveness and ROI?

Understanding Your Requirements

Start by evaluating your organization’s quality management needs. Factor in industry requirements, current challenges and future growth. Identify essential features for supporting quality processes and distinguish must-haves from nice-to-haves. It will shape your selection process.

Evaluating System Architecture

Decide between a cloud-based or on-premises solution based on your needs. Cloud systems offer flexibility and easy updates but may have security risks, while on-premises solutions offer more control but need more resources. Choose the option that fits your IT and security requirements.

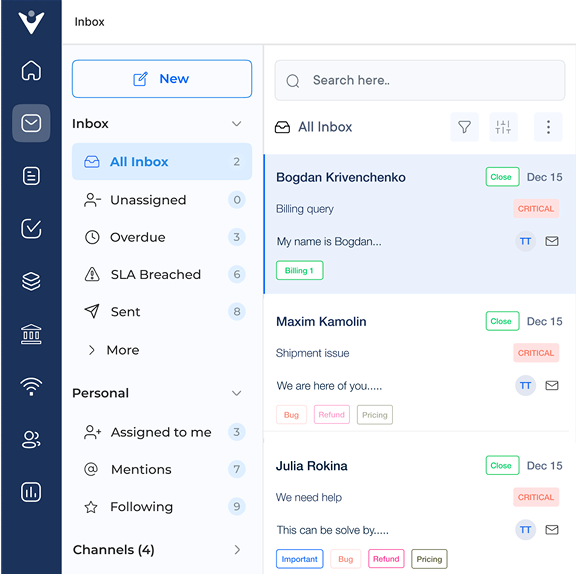

Assessing User-Friendliness

Choose a system that’s user-friendly for all employees, with a minimal learning curve. Look for customizable dashboards, easy navigation and mobile access. A powerful system is only effective if it’s easy to use it.

Integration Capabilities

Ensure your quality management system integrates smoothly with existing tools like ERP, document management and CRM platforms. The integration streamlines data flow and prevents silos that could hinder quality control.

Implementation Support

Assess the vendor’s implementation process, training and support services. Their industry experience and ability to guide you during setup are crucial for the success of your quality control system.

Cost Considerations

Consider the total cost of ownership, including implementation, training, maintenance, updates and customization. A higher upfront cost may be more cost-effective long-term if it better supports your growth.

Real-World Examples of Quality Management

Below are some compelling real-world examples of quality management in action, showing how different organizations have implemented the principles to achieve remarkable success.

Toyota Production System

Toyota’s quality management system highlights continual improvement (Kaizen) and a process-driven approach. It integrates quality checks at every stage, empowers employees to halt production for defects and ensures thorough documentation with standardized work procedures.

The focus on quality has cemented Toyota’s reputation as one of the most reliable car manufacturers. Their approach has boosted customer loyalty, reduced warranty claims and inspired the widely adopted “Lean Manufacturing” practices across industries.

Amazon Customer Service

Amazon’s customer-centric quality management prioritizes feedback and data-driven decisions. Their “Customer Obsession” principle guides everything, from website design to delivery services, through continuous customer behavior analysis.

The focus on customer satisfaction has transformed Amazon from a small bookstore into a global retail leader. Their quality assurance practices have built a trusted brand and high customer loyalty, setting new standards in e-commerce service.

Mayo Clinic Healthcare

Mayo Clinic’s quality control system blends evidence-based decision-making with employee engagement. They uphold healthcare excellence by focusing on continuous medical education, standardized protocols and rigorous peer reviews.

The approach has solidified the Mayo Clinic as a global healthcare leader, driving better patient outcomes, fewer medical errors and setting a quality benchmark that others aim to follow.

Apple Product Development

Apple’s quality assurance is built on design perfection and rigorous testing. Having a meticulous process-driven approach and strong supplier partnerships, Apple ensures every product meets its high standards of innovation and reliability.

The commitment to quality has reinforced Apple’s premium position in the tech market, delivering reliable products with exceptional user experiences. Their rigorous quality control drives brand loyalty and allows them to command premium prices.

Starbucks Service Quality

Starbucks’ quality management system focuses on employee training and standardized service procedures, supported by strong leadership commitment. It ensures consistent service quality across thousands of global locations.

Their commitment to quality has cultivated a global coffee culture and solidified their brand identity. Starbucks’ quality practices have set a benchmark for service excellence in the food and beverage industry.

Key Challenges in Quality Management

Check out the common quality management challenges that organizations face and how to effectively address them.